We have four factories: indoor cable production factory; outdoor cable production factory; optical accessories production factory; communication mold production factory.

Indoor Optical Cable Factory:

It has 13 production lines and covers an area of 15,000 square meters. There are 80 employees, including 13 R&D personnel. The annual output value is 11 million US dollars. Indoor tight-buffered optical cable production capacity: 1,500km/day.

Main products: drop cable, distribution cable, round cable, figure 8 cable, etc.

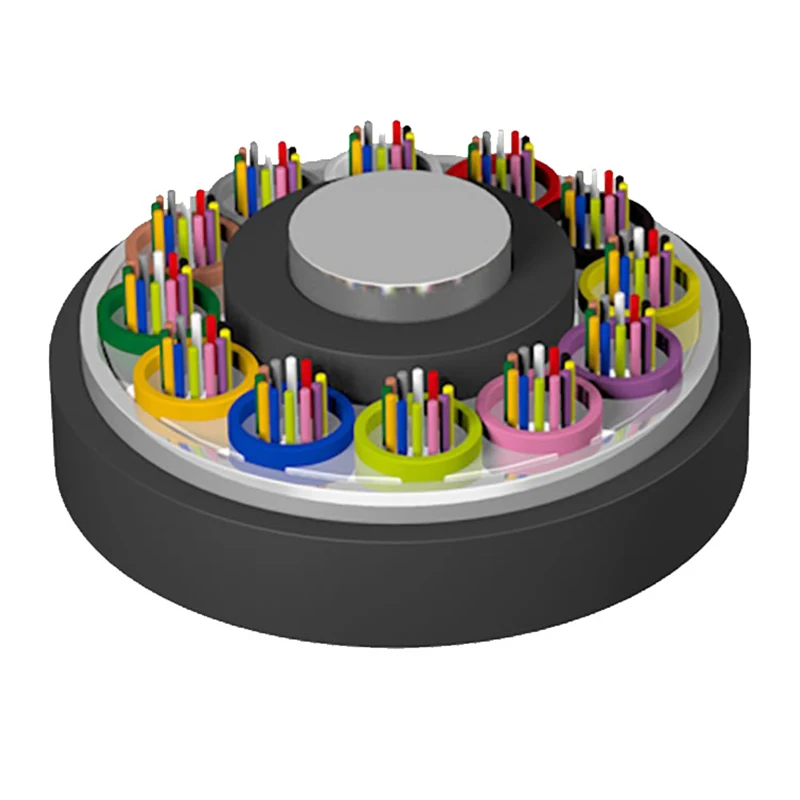

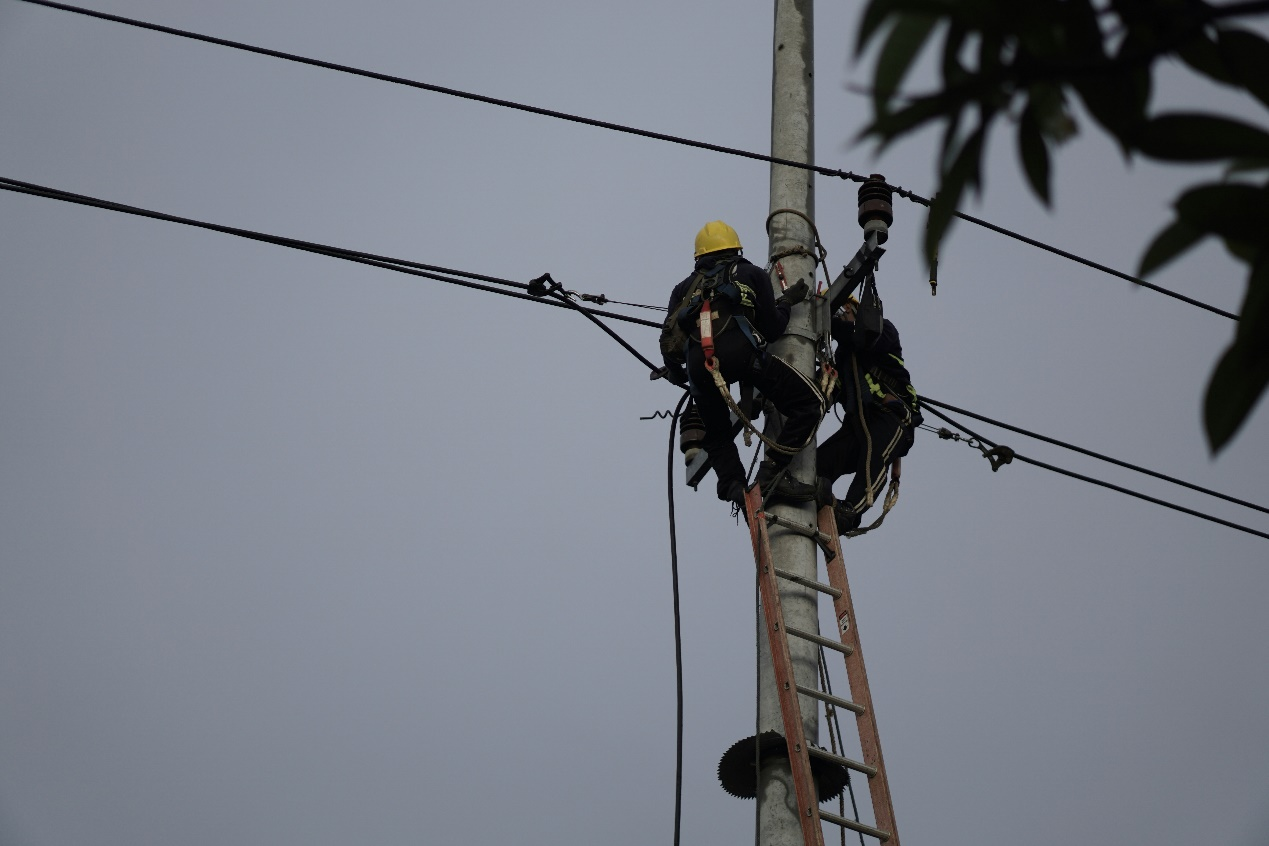

Outdoor Optical Cable Factory:

It has 8 production lines including optical fiber coloring machine, jacketing machine, molding machine, extruder, etc. The company currently has 110 employees, including 22 R&D personnel. It covers an area of 15,000 square meters. The annual output value is 28 million US dollars. Outdoor loose tube optical cable production capacity: 300km/day.

Main products: duct optic cable, armored optic cable, direct buried optical cable, ADSS, aerial optical cable, air-blown micro cable, etc.

Fiber optic cable loose tube plastic coating

production line

Fiber optic cable twisted into cable

production line

Fiber optic coloring

production line

Fiber optic ribbon banding machine

production line

Fiber optic tape plastic

production line

Optical cable outer sheath extrusion

production line

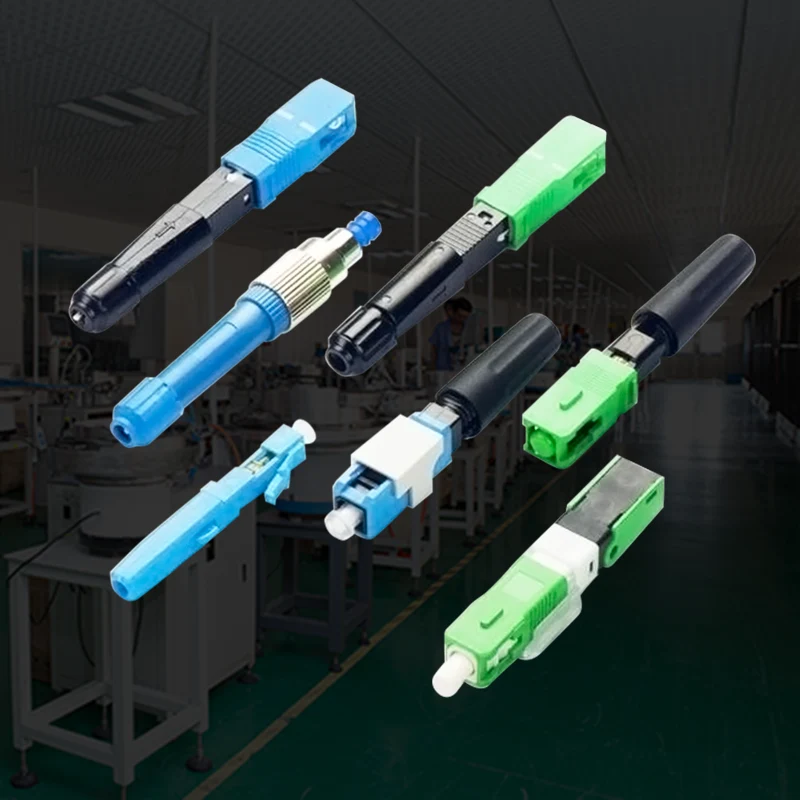

ODN Optical Component Factory:

It has three studios covering an area of 7,500 square meters. There are 180 employees, including 32 development and technical engineers. The annual output value is about 13 million US dollars.

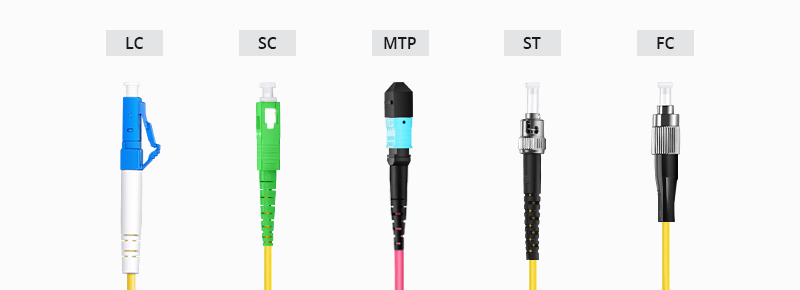

Main products: pigtails, patch cord, PLC, adapters, connectors, etc.

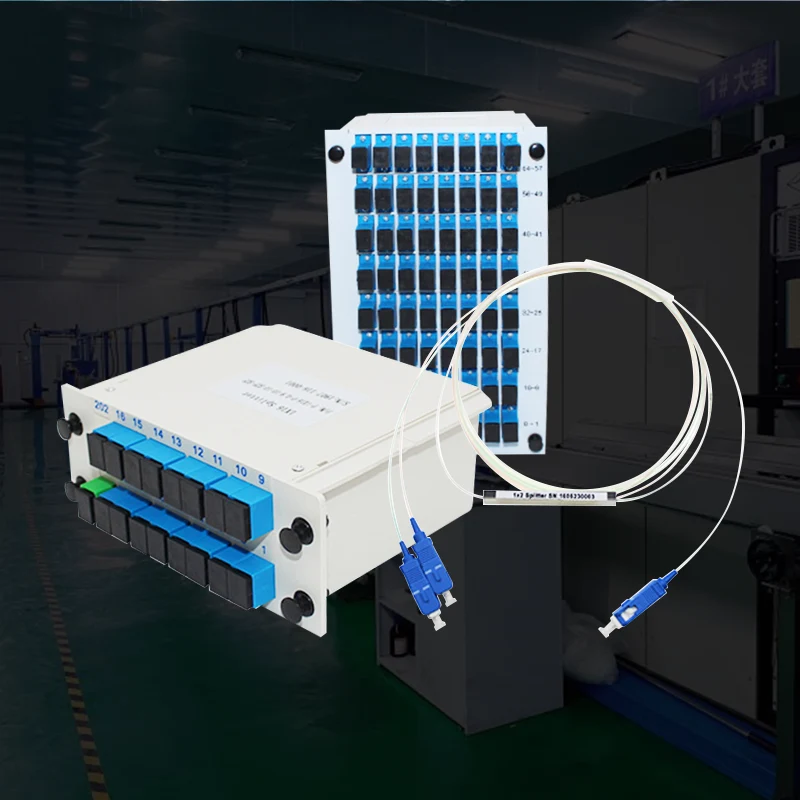

Optical Network Equipment Factory:

Integrating production and trade, the factory has a total area of 5,000 square meters, with 4 fully automatic mold production equipment and 7 production lines. There are 70 employees, including 12 development technical engineers, and the annual output value exceeds 5 million yuan.

Main production: patch panel, distribution box, and cable splice closure, etc.

OUR LABORATORY

Our laboratory has a complete set of equipments to strictly control the quality.

Tests can be carried out in the following aspects:

Optical Performance: Test the optical fiber and finished optical cable to ensure the optical performance and attenuation coefficient of each transmission.

Appearance and Specifications: Check the appearance, structure, length, outer diameter, and outer diameter thickness of the loose tube.

Mechanical Properties: Tensile, minimum bending radius, high and low temperature tests of the optical cable.

Physical Properties: Check the mechanical and physical properties of the sheath.

Equipment List:

OTDR

optical fiber geometry testing system

optical fiber ribbon geometry testing system

optical fiber multiparameter testing system

fiber optic stretching system

microcomputer controlled electronic universal testing machine

single insulated wire or cable vertical flaming tester

environmental stress cracking tester

oxygen index tester

alternating high and low temperature test chamber

Differential Scanning Calorimeter

Environmental Stress Cracking Tester

Fiber Optic Stretching System

Optical Fiber Ribbon Geometry Testing System

OTDR

Alternating High and Low Temperature Test Chamber 2

Alternating High and Low Temperature Test Chamber 3

Electromechanical Universal Testing Machine

Precision Optical Image Measuring Instrument

Single Insulated Wire or Cable Vertical Flaming Tester