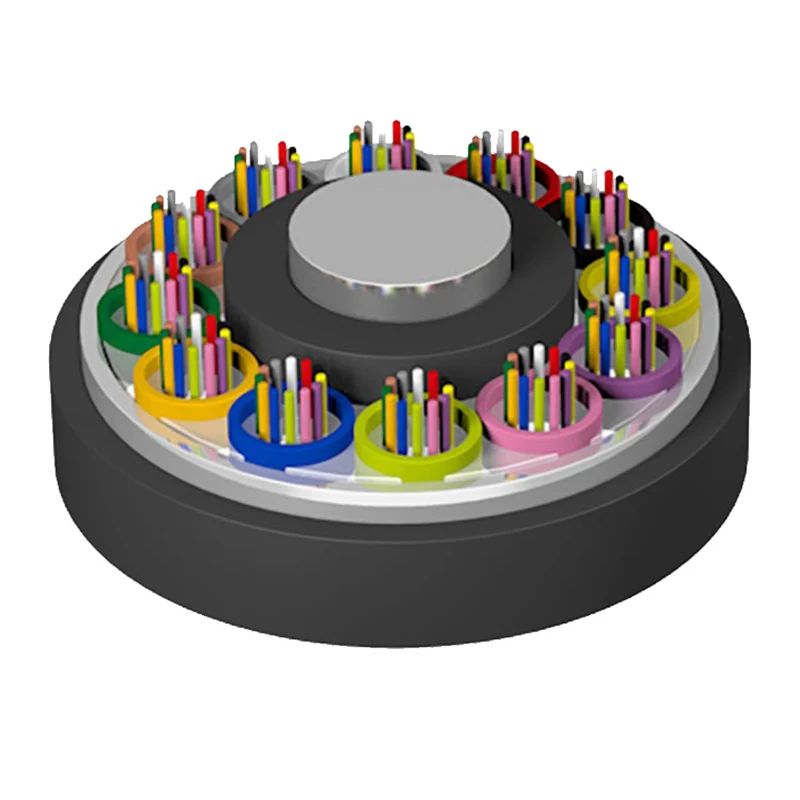

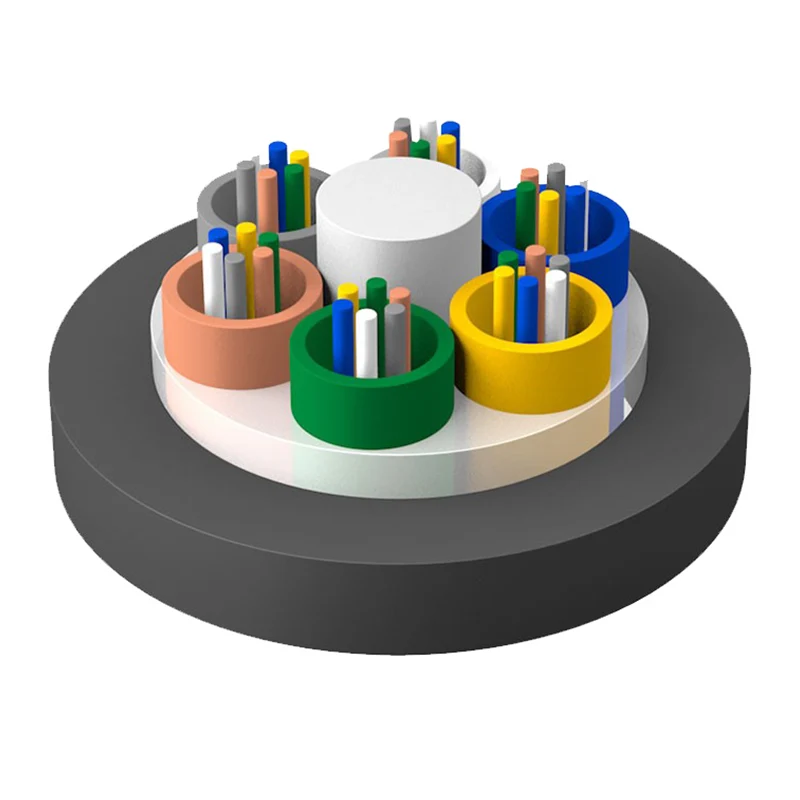

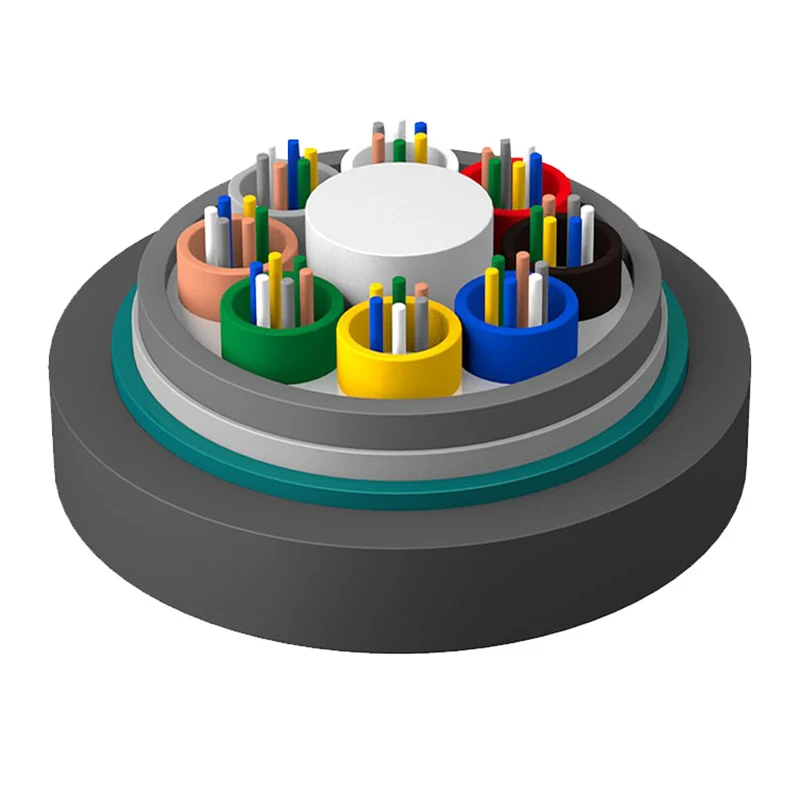

Outdoor duct cables are designed for installation in underground conduits. They primarily protect the cables from external environmental influences, ensuring the stability and reliability of optical signal transmission. Outdoor duct cables typically feature robust jackets and armor layers that resist physical damage, such as compression and impact. The conduit provides additional protection against soil corrosion, moisture ingress, and animal bites. Duct cables can be quickly installed through conduits, reducing the need for excavation and restoration work. The cables are easy to locate and maintain, lowering the difficulty and cost of future maintenance. Outdoor duct cables are widely used in long-distance communication lines and inter-office connections, ensuring high-capacity, long-distance optical signal transmission. In metropolitan network construction, outdoor duct cables connect various nodes and data centers, providing high-speed, stable data transmission channels. In situations requiring special protection, such as crossing rivers, highways, or railways where direct cable installation is challenging, duct cables can be installed through conduits.

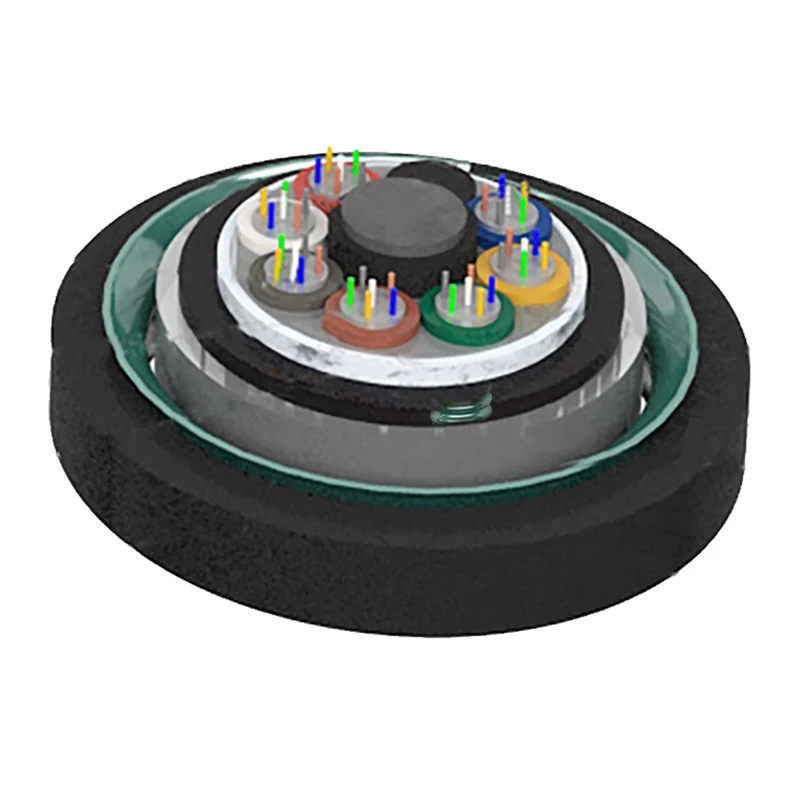

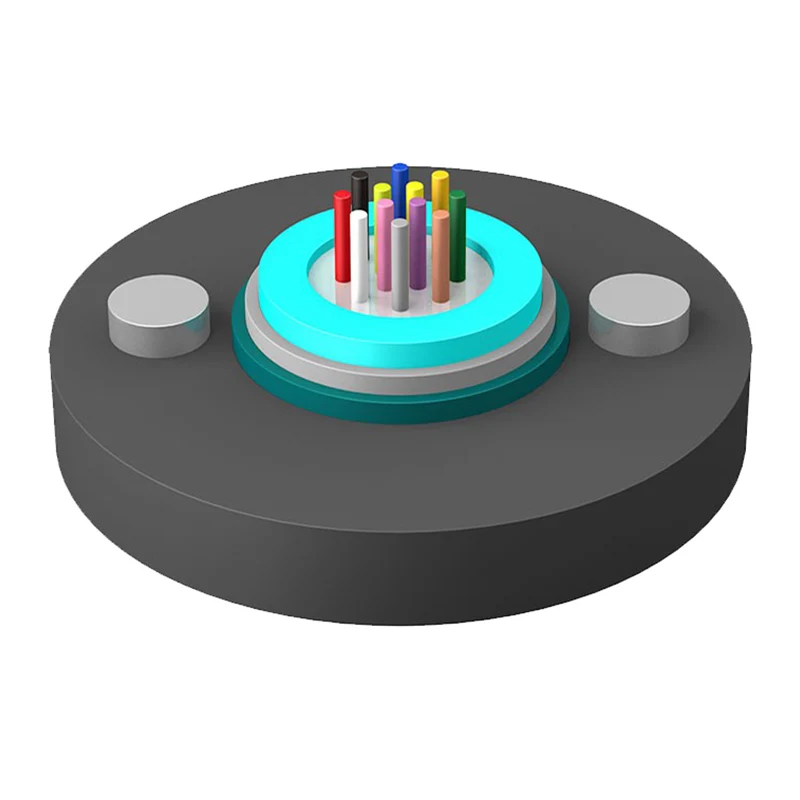

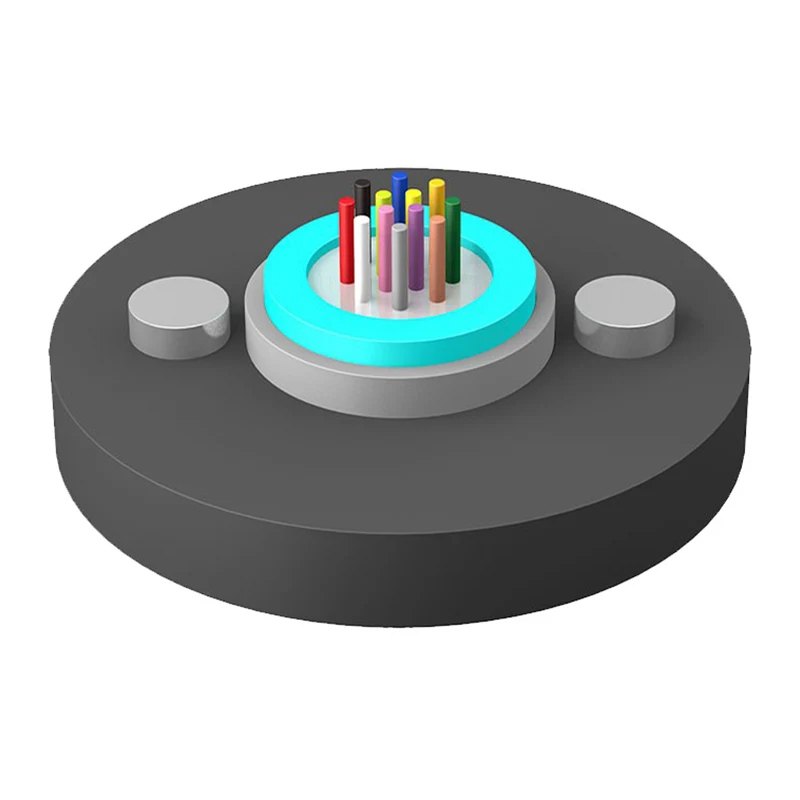

Outdoor aerial cables are suspended between utility poles or power towers for long-distance outdoor communication transmission. They usually feature insulating materials and robust structural designs to ensure stable operation in harsh weather and natural environments. Outdoor aerial cables typically have thick jackets and reinforcement components, such as aramid or steel wires, to provide sufficient tensile strength, preventing the cables from breaking under wind force and their own weight. The cable jackets are made from corrosion-resistant and aging-resistant materials, protecting against UV rays, rain, snow, and ice, thus extending the lifespan of the cables. The installation of aerial cables is relatively simple, utilizing existing utility poles or power towers, which reduces the need for excavation and restoration work. Aerial cables are easy to locate and maintain, lowering the difficulty and cost of future maintenance.

Outdoor aerial cables are commonly used to connect cities or regions, providing high-speed, stable data transmission services. In specialized networks such as power, transportation, and energy, aerial cables connect various nodes and terminal devices, enabling real-time information transmission and monitoring. Welcome everyone to buy our duct and aerial cables!